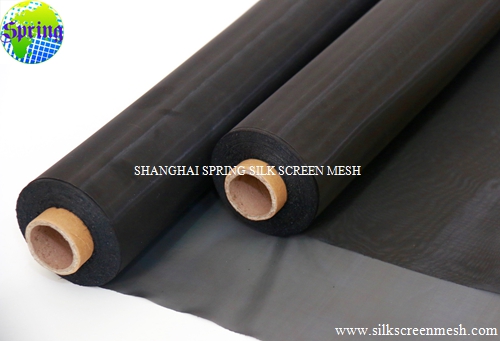

Black Mesh

Hydrophobic Acoustic Mesh, Waterproof - Allows Air to Pass

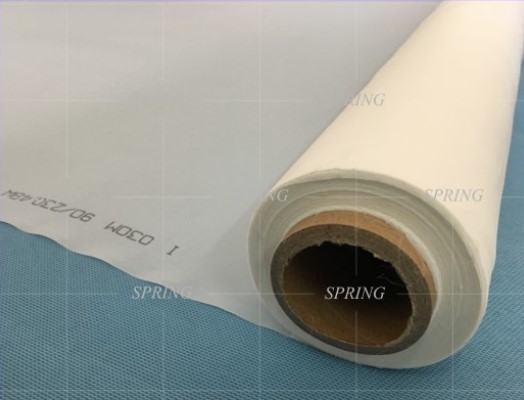

| Introduction: Hydrophobic acoustic mesh is a type of material that is designed to provide both acoustic insulation and water resistance. It is typically made from a combination of hydrophobic materials, such as PTFE or silicone, and sound-absorbing materials, such as fiberglass or foam. The hydrophobic properties of the material allow it to repel water, preventing it from penetrating the structure it is applied on. This makes it ideal for use in marine environments, where exposure to water and moisture is common. At the same time, the acoustic properties of the material allow it to absorb sound waves, reducing noise pollution and improving acoustic performance. It can be used in a variety of applications, including automotive, aerospace, construction, and marine industries. Spring As a professional manufacturer vendor of Hydrophobic Acoustic Mesh can provide you with high-quality fabric to satisfy your demand. SPRING Hydrophobic Acoustic Mesh is a good choice for you. We can produce from 8mesh/cm(20mesh) to 240mesh/cm(600mesh) mesh size with different widths and colours, and the maximum width can reach 373CM. The usual colours are white, yellow and black. Shanghai SPRING can satisfy all your requests for your acoustic mesh, SPRING can manufacture special types to meet our customer’s different demands. |

|

Application:

Hydrophobic acoustic mesh is a material that combines hydrophobic properties with acoustic insulation capabilities. This type of material has several potential applications in various industries, including:

1. Marine: Hydrophobic acoustic mesh can be used in marine environments to reduce noise and vibration. It can be installed on ship hulls, bulkheads, and decks to provide sound insulation and prevent water from penetrating the structure.

2. Automotive: In the automotive industry, hydrophobic acoustic mesh can be used to reduce engine and road noise inside the vehicle cabin. It can also improve the acoustic performance of speakers and other audio equipment by reducing the amount of sound waves reflecting off hard surfaces.

3. Aerospace: Hydrophobic acoustic mesh can be used in aerospace applications to provide sound insulation and reduce vibration. It can be installed in aircraft cabins, cargo bays, and engine compartments to improve passenger comfort and reduce noise pollution.

4. Construction: In the construction industry, hydrophobic acoustic mesh can be used as a building material for walls, floors, and roofs to provide thermal insulation and soundproofing. It can also be used to reduce noise pollution in urban areas by installing it in buildings near busy roads or airports.

Overall, the hydrophobic acoustic mesh has many potential applications where both acoustic insulation and water resistance are required. Its unique properties make it an attractive material for use in various industries.

Specification:

| Type | Weave | Acoustic Resistance (MKS Rrays) |

Thickness (um) |

Mesh Opening(um) | Open Area (%) |

Material | |

| SG006a | PW | 6 | 40 | 85 | 60 | PET | |

| SG006 | PW | 6 | 65 | 105 | 52 | PET | |

| SG008 | PW | 8 | 175 | 150 | 34 | PET | |

| SG009 | PW | 9 | 50 | 78 | 50 | PET | |

| SG010 | PW | 10 | 108 | 115 | 39 | PET | |

| SG015 | PW | 15 | 45 | 50 | 43 | PET | |

| SG020 | PW | 20 | 65 | 67 | 38 | PET | |

| SG025 | PW | 25 | 50 | 53 | 40 | PET | |

| SG032 | TW | 32 | 49 | 38 | 31 | PET | |

| SG042 | TW | 42 | 49 | 29 | 29 | PET | |

| SG045 | TW | 45 | 120 | 50 | 19 | PET | |

| SG047 | PW | 47 | 52 | 36 | 28 | ||

| SG050 | TW | 50 | 50 | 30 | 26 | PET | |

| SG065 | TW | 65 | 58 | 30 | 24 | PET | |

| SG075 | TW | 75 | 51 | 25 | 20 | PET | |

| SG080 | TW | 80 | 56 | 23 | 26 | PET | |

| SG090 | TW | 90 | 128 | 40 | 14 | PET | |

| SG095 | PW | 95 | 60 | 32 | 20 | PET | |

| SG145 | TW | 145 | 72 | 27 | 14 | PET | |

| SG160 | TW | 160 | 62 | 20 | 15 | PET | |

| SG260 | TW | 260 | 63 | 18 | 13 | PET | |

| SG410 | TW | 410 | 64 | 15 | 9 | PET | |

| SG600 | TW | 600 | 65 | 12 | 7 | PET | |

| SG1050 | TW | 1050 | 87 | 10 | 3 | PET | |

| SG4000 | TW | 4000 | 88 | 7 | 2 | PET |

How does the Hydrophobic acoustic mesh used in optical components?

Hydrophobic acoustic mesh is a type of material that is used in optical components to reduce the amount of moisture and debris that can accumulate on their surfaces. This is important because contaminants can affect the performance of optical components, causing them to degrade or fail over time.

The hydrophobic acoustic mesh is made up of tiny fibers or particles that are coated with a hydrophobic material, which means that they repel water. When this material is applied to the surface of an optical component, it creates a barrier that prevents water droplets from adhering to the surface. Instead, the water beads up and rolls off the surface, taking any debris or contaminants with it.

In addition to its hydrophobic properties, the acoustic mesh is also designed to absorb sound waves and vibrations. This helps to prevent unwanted noise and interference from affecting the performance of the optical component.

Overall, the use of hydrophobic acoustic mesh in optical components is an effective way to improve their durability and longevity, while also maintaining their performance in challenging environmental conditions.

Features & advantages:

The hydrophobic acoustic mesh has several features and advantages that make it well-suited for use in optical components. Some of these include:

-

Hydrophobic Properties: As mentioned earlier, the hydrophobic acoustic mesh is coated with a material that repels water droplets. This property helps to prevent moisture from accumulating on the surface of the optical component, which can cause it to degrade over time.

-

Sound Absorption: The acoustic mesh is also designed to absorb sound waves and vibrations. This feature helps to reduce unwanted noise and interference that can affect the performance of the optical component.

-

Durability: The hydrophobic acoustic mesh is highly durable and can withstand harsh environmental conditions such as extreme temperatures and humidity. This makes it an ideal choice for use in optical components that are exposed to challenging operating conditions.

-

Easy to Clean: Because the hydrophobic acoustic mesh repels water, it is also easy to clean. Any debris or contaminants that accumulate on the surface of the mesh can be easily removed by simply rinsing it with water.

-

Improved Performance: By reducing the amount of moisture and debris that can accumulate on the surface of an optical component, the hydrophobic acoustic mesh can help to maintain its performance over time. This means that the optical component can continue to function effectively even in challenging environmental conditions.

Overall, the combination of hydrophobic and acoustic properties makes the hydrophobic acoustic mesh a highly effective material for use in optical components. Its durability, easy-to-clean surface, and performance-enhancing qualities make it an ideal choice for a wide range of applications.

| Material | 100% Polyester |

|---|---|

| Weave | Plain, Twill |

| Monofilament | Yes |

| Color | White, yellow, orange, black |

| Width | 0.5-3.73M |

| Mesh Count | 18mesh-600mesh, 8/cm, 10/cm, 12/cm, 16/cm, 20/cm, 24/cm, 32/cm, 39/cm, 43/cm, 48/cm, 54/cm, 62/cm,72/cm, 80/cm, 90/cm, 100/cm, 120/cm, 140/cm, 150/cm, 165/cm, 180/cm, 200/cm, 240/cm |

| Mesh Opening | 3-1080 micron |

| Wire diameter | 27um-400um |

| Elongation | Low |

| Tension | High |

| Type | mesh in rolls, round disc, square pieces, butterfly shape, circle shape, etc. |

SPRING Black Polyester silkscreens mesh adavantages:

1. Hi Transparency

2. The mesh opening is uniform and the size is stable

3. Large opening rate

4. Uniform and consistent thickness.

Factory Show:

\

\

Certification: RohS